Compression versus Load: what should you use?

Lotfi Grine, Eng. – Product Specialist at Robco

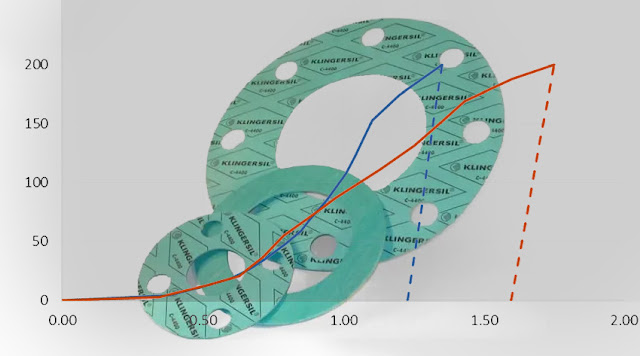

One common question concerning sealing tightness with flat gasket materials is the proper compression percentage or/ and the amount of force needed to compress them. This is a critical design parameter. These two parameters can affect the number, type, size and spacing of attachments like bolts to prevent housing deflection, flange rotation and subsequent leakage.

Because several gasket materials consist in a composite, like semi-metallic or compressed sheet gasket materials, it is the level of torque (load), rather than the level of gasket compression expressed in percentage that matters. This level of torque will be chosen according to different parameters like bolts grade, flange type, maximum and minimum sealing stress, etc.

For Klinger compress sheets and gaskets, Robco uses KLINGERexpert software to assist users for improved scientific calculations of bolt torque requirements. A similar program is used for semi-metallic gaskets.

When can I use percentage?

Things are a bit different in the case of elastomeric (rubber) gaskets to form a proper seal. In addition to calculating the proper torque, we can also evaluate, based on how much (in percentage) the material is compressed from its original thickness. If you ever changed the small gasket of a garden hose, you already know that a rubber gasket that is compressed too much or too little will not form a proper seal. As a rule of thumb, the ideal compression percentage depends on the rubber durometer:

30 to 50% maximum for soft rubber and up to 60 durometer shore A

No more than 15 to 25% for harder rubber materials with a durometer of 70 or more

ASTM D395 is a standard from ASTM that defines three different test methods (A, B, and C) for Compression Set in rubber materials. Typically, Test Method B is used

Compression Force Deflection (CFD) measures firmness and is defined in ASTM standard D1056 as the force needed to reduce the material by 25% in thickness.

Comments

Post a Comment