Sizing Semi-Metallic Gaskets When Replacing Soft Gaskets

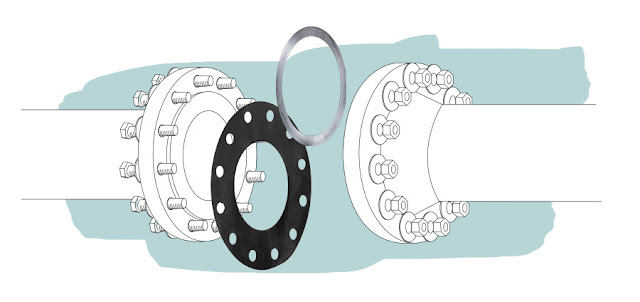

When replacing soft gaskets with semi-metallic gaskets, it's important to understand the sizing differences and considerations. The following guidelines provide suggested dimensions based on experience to help you choose the appropriate non-metallic gasket size to replace a soft gasket. These sizings are not mandatory but serve as useful recommendations.

1. When Flange Dimensions Are Provided

If the customer provides the dimensions of the flange, the following guidelines can be used to determine the appropriate gasket size:

Gasket Inner Diameter (I.D.): The inner diameter of the gasket should be the bore size of the flange plus a minimum of 1/8".

Gasket Outer Diameter (O.D.): The outer diameter can be up to the bolt hole circle diameter minus one bolt hole diameter. This applies when the proposed gasket width corresponds to the standard width of semi-metallic gaskets, which is typically 1/2", 3/4", or 1".

If the desired gasket width does not match these standard widths, you can choose an appropriate standard width for the gasket and use an outer ring to centralize the gasket. This approach helps in maintaining the proper placement and sealing effectiveness. For example, you might consider using the Maxiprofile type LA1 or LA3 to achieve the desired fit.

2. When Soft Gasket Dimensions Are Provided

If the customer provides the dimensions of an existing soft gasket, you can follow these steps to specify the dimensions for a semi-metallic gasket:

Semi-Metallic Gasket Inner Diameter (I.D.): This should be the same as the inner diameter of the soft gasket.

Semi-Metallic Gasket Outer Diameter (O.D.): The approach for determining the outer diameter is the same as described above. Ensure the O.D. is up to the bolt hole circle diameter minus one bolt hole diameter, depending on the standard width of the gasket.

Conclusion

Replacing soft gaskets with semi-metallic ones requires careful consideration of the gasket dimensions to ensure a proper fit and effective sealing. By following the above guidelines based on either flange or existing soft gasket dimensions, you can make an informed decision on the appropriate gasket size. Remember, while these suggestions are based on industry experience, always verify the sizing with the specific requirements and conditions of the application.

Comments

Post a Comment